Pure Carbon Performance Redefined

Engineered for modern industrial challenges, Expanded Graphite Gland Packing represents the pinnacle of thermal sealing technology. Unlike conventional braided packings, our 100% pure expanded graphite structure delivers unmatched heat dissipation while maintaining exceptional chemical inertness – making it the ideal choice for extreme-temperature applications where traditional materials fail.

Where Conventional Packings Fall Short

🔥 High-Temperature Process Valves (up to 650°C continuous)

⚡ Power Plant Superheated Steam Systems

🧪 Corrosive Chemical Reactors (resists 98% H₂SO₄ & 50% NaOH)

🛢 Refinery Flare Stack Seals (API 622 compliant)

🧊 Cryogenic LNG Pumps (-200°C cold box applications)

Material Science Breakthrough

| Property | Test Method | XG-9000 Series | Traditional Graphite |

|---|---|---|---|

| Thermal Conductivity | ASTM E1461 | 120 W/m·K | 25-35 W/m·K |

| Compression Recovery | API 622 | 98% | 85-90% |

| Oxidation Threshold | TGA Analysis | 550°C (in air) | 450°C |

| Particle Shedding | ISO 8573-1 | Class 1 | Class 3 |

| Sealability Index | ISO 15848 | AH Class | BH Class |

Engineered for Critical Service

Multi-Directional Flexibility

• Isotropic Structure – Equal performance in radial/axial directions

• Memory Retention – Returns to original thickness after decompression

• Layered Design – Customizable density (0.8-1.3 g/cm³)

Advanced Manufacturing Process

✓ Electrostatic Expansion – Creates uniform pore structure

✓ Rolling Calendaring – Achieves precise thickness tolerance (±0.05mm)

✓ Laser Quality Control – 100% surface defect detection

Unmatched Technical Advantages

1. Thermal Superconductor

• 4X faster heat transfer than braided graphite

• Prevents gland overheating in steam applications

2. Chemical Immunity

• pH stable from 0-14

• Zero chemical degradation in sour gas (NACE MR0175 certified)

3. Maintenance Optimization

• 50% longer service intervals vs. conventional packing

• No break-in period required

4. Emission Control

• TA-Luft compliant (leakage <50 ppmv)

• EPA Method 21 verified

Specialized Configurations

- XG-9100HT – With Inconel foil reinforcement (800°C intermittent)

- XG-9200FM – FDA-compliant for food processing

- XG-9300AT – Anti-static version for explosive atmospheres

Industry Validation

▶ 12,000+ hours continuous operation in geothermal wellheads

▶ Zero unplanned downtime in FCCU reactor valves

▶ 100% success rate in ISO 15848 Type Testing

(Technical datasheets and material samples available upon request)

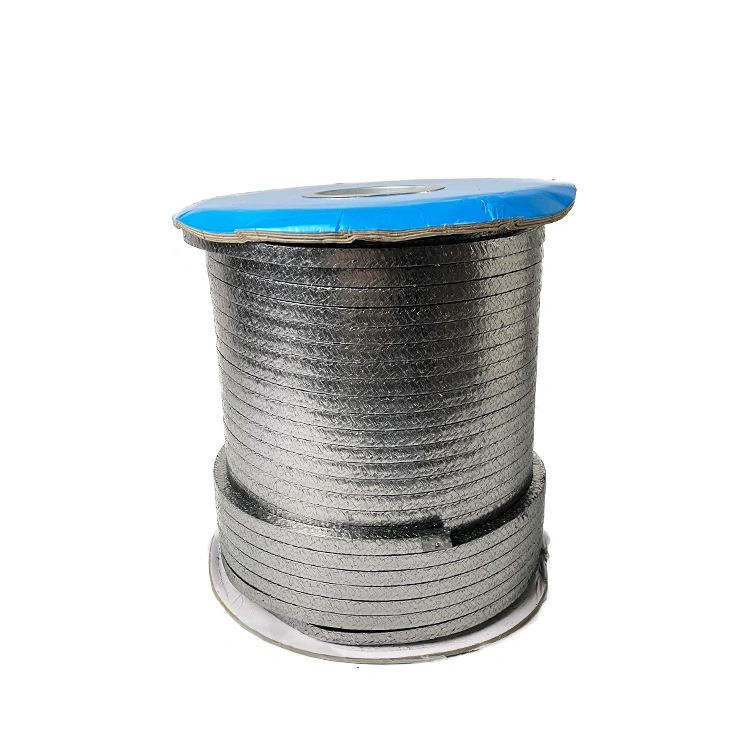

Expanded Graphite Gland Packing

Hongwo Braided Packing

Hongwo Braided Packing

Scan the QR Code to start a WhatsApp chat with us.